refractories

refractories

Types and Features of our Refractories

Cement, lime, steel, non-ferrous metals, glass, paper and pulp, and other materials essential to our daily lives are made through a high-temperature heat treatment process. The use of refractory materials is essential for this process. We have three plants that manufacture basic bricks, high-alumina bricks, alumina-chromia bricks, SiC bricks, special shaped refractories, and various monolithic refractories.

Mino’s Refractories

Mino’s Advantage

-

point01

High share for the domestic refractory market for cement, lime, and pulp & paper industry

-

point02

We have a wealth of experience and know-how in a wide range of fields, including the environmental field, various ceramic industries, non-ferrous metals, and glass.

-

point03

We have a production system that is capable of manufacturing small quantities of a wide variety of high value-added products.

-

point04

Manufacturing, technology and sales are all integrated and have a meticulous after-sales service system.

| Applications | Various material manufacturers, high temperature heat treatment processes |

|---|---|

| Products | Shaped refractories, Monolithic refractories |

| Industries | Cement,Lime,Environment,Iron & Steel,Non-ferrous metals,Glass,Paper & Pulp etc. |

| Main fields of application | Shaped and monolithic refractories for cement manufacturing facilities, lime kilns, glass melting facilities, various smelting furnaces, copper converters, waste incineration facilities, waste melting facilities |

The strength of

Mino Ceramics’ refractories

Mino Ceramics’ refractories are used mainly in cement and lime, but also in environmental plants, steel, non-ferrous metals, glass, chemicals, electrodes, electronic products, and many other industries. Through the manufacturing plants and manufacturers of our customers and suppliers, refractories are connected to familiar products such as smartphones and PCs, automobiles, food and beverage cans, and ceramics. Refractories are essential for these products, as they require heat treatment at high temperatures in the manufacturing process. Mino Ceramics provides refractories to help manufacturers and material suppliers create products that support our daily lives.

-

Cement

-

Lime

-

Non-ferrous

-

Iron and steel

Glass

-

Environmental recycling

-

Renewable energy

Types of

Mino Ceramics Refractories

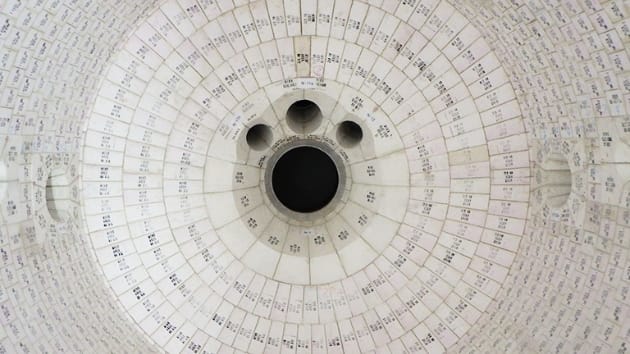

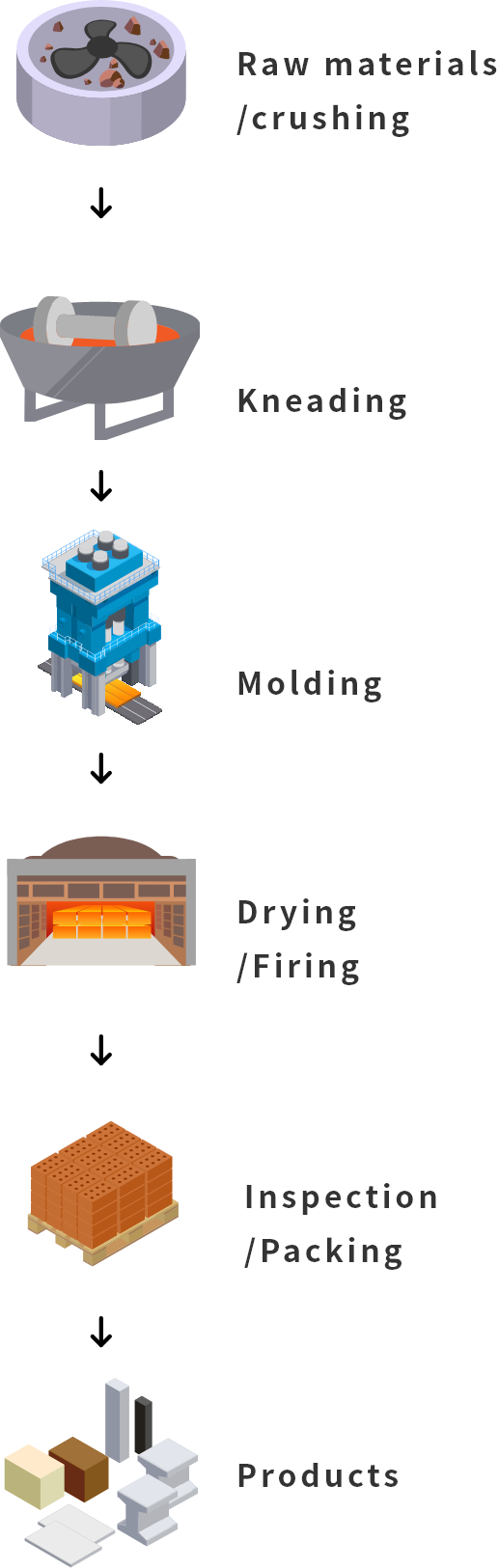

Shaped refractories

Based on the know-how accumulated over many years A wide variety of shaped products can be supplied

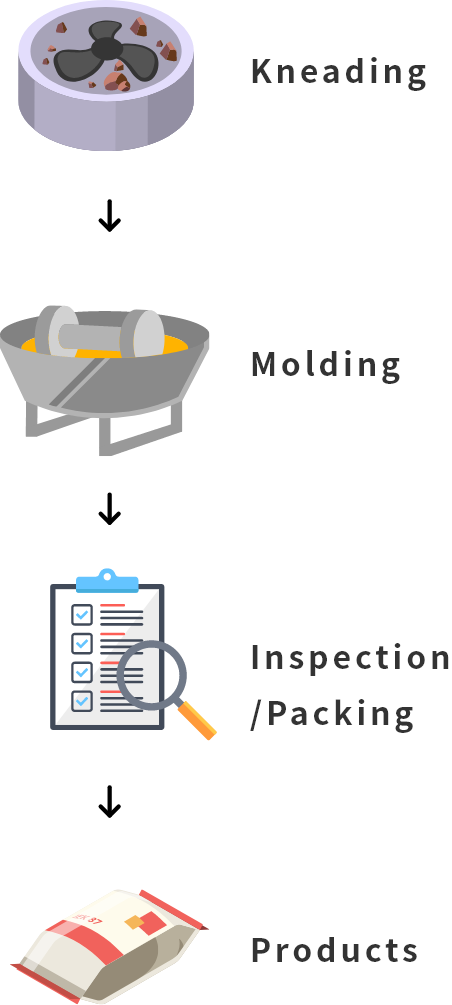

Shaped refractories are manufactured through the processes of kneading, molding, and firing. Strength is developed by firing, and handling on site is easy.

-

Basic bricks

-

Clay and high-alumina bricks

Alumina-chromia bricks -

Combined Alumina・

Silica bricks

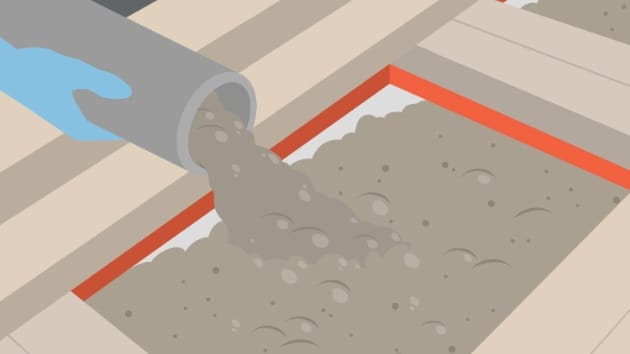

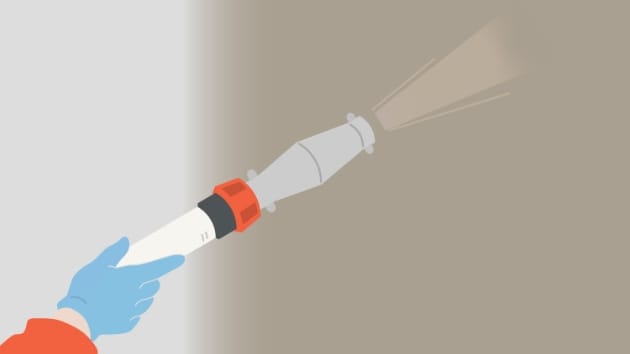

Monolithic refractories

A wide range of irregular shaped products are available according to the furnace environment and construction method.

Monolithic refractories are shipped with a pre-mixed refractory aggregate, suitable binders and additives. The best construction method can be selected according to the site conditions, such as pouring, spraying, patching, etc., by kneading with water or a specific kneading liquid on site.

-

Pouring

-

Spraying

-

Patching

Mino Ceramics’ refractory

production flow

Shaped refractories

Monolithic refractories

engineering

engineering

Mino Ceramics

Refractories Engineering Division

The Refractories Engineering Division is engaged in the design and construction of refractories manufactured in-house for plants mainly in the fields of cement, lime, environment and recycling, as well as proposal-based technical services. Various types of special refractories, from basic, alumina-chromium, high-alumina, SiC, and clay refractories (bricks) or monolithic refractories (castables), are used to provide high added value in response to our customer needs.

Engineering at Mino Ceramics

Mino’s Advantage

-

point01

Mino Ceramics offers a full range of refractory engineering services, from manufacturing to design and construction and proposal-based technical services.

-

point02

Comprehensive engineering that covers everything from canning and heat insulation of furnace bodies to lining furnace materials

| Applications | Furnace material engineering for industrial furnaces |

|---|---|

| Examples | Cement: Cement rotary kiln, pre-heater, cooler, etc. Lime: Bekenbach furnace, Shaft furnace, Top-shaped furnace, Merz furnace, Rotary kiln, etc. Waste treatment: Stoker type incinerator, Rotary kiln type melting furnaces, Gasification melting furnaces, various boilers, etc. |

| Industries | Cement, lime, waste treatment, paper processing, non-ferrous metals, various ceramic industries |

| Characteristies | Shaped and monolithic refractory construction, furnace material design, construction, and improvement proposals, one-of-a-kind furnace material engineering |

Engineering examples

-

Cement field

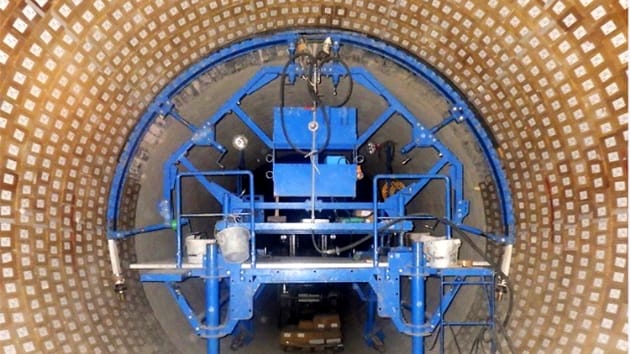

Construction of cement rotary kiln bricks

-

Lime field

Construction of lime Bekenbach furnace bricks

-

Environmental Field

Construction of bricks and castables for rotary kiln type melting furnace

Japanese distributor of FLSmidth Cement

As a distributor of FLSmidth Cement, which is the one of the largest industrial supplier to the global cement industry, in Japan, we provide maintenance services for rotary kilns and rotary dryers. We also handle various FLSmidth Cement products related to rotary equipment maintenance.

new ceramics

new ceramics

New ceramics

Features and Applications

Mino Ceramics contributes to the electronics and advanced technology with kiln furniture (firing tools) that can withstand ultra-rapid firing and ceramics (oxides and non-oxides) with new features that have never been seen before. Our kiln furniture has been well received in the electronics industry, and our ceramics (oxides and non-oxides) are attracting attention in advanced fields such as the aerospace industry and the nuclear power industry.

Our New Ceramics

Mino’s Advantage

-

point01

Firing tool materials and fine ceramics (oxides and non-oxides) and fine ceramics (oxides and di-oxides) in a single process

-

point02

Technology development and production system that can respond to a variety of needs

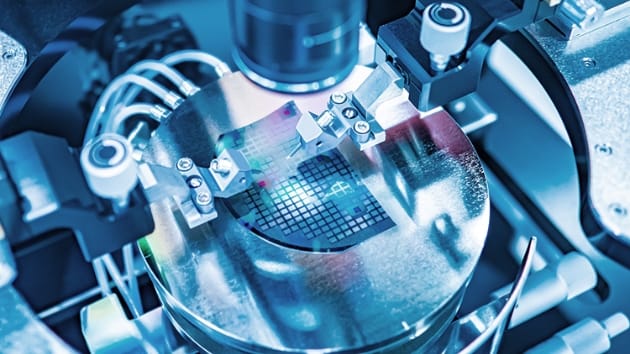

| Applications | Firing tool materials (electronic parts, secondary batteries, fuel cells, various ceramic raw materials, etc.), parts for semiconductor manufacturing equipment, various ceramic parts, etc. |

|---|---|

| Examples | Setters for firing MLCCs, fuel cells, etc., mechanical seal parts, small ceramic parts |

| Industry | Elecrotonics, aerospace industry, nuclear power industry |

| Main fields of application | De-binder in various firing processes, improvement of temperature distribution and speeding up of firing, improvement of fuel efficiency by weight reduction, reaction prevention materials, semiconductor manufacturing equipment |

Advantages of our New Ceramics

-

Ventilation Setters

With its high air permeability, excellent degreasing performance, and temperature-following characteristics, this product is attracting attention for its ability to manufacture electronic components with energy-saving and stable quality.

-

B4C (normal pressure sintered boron carbide)

With a hardness second only to that of diamond, this material is attracting attention in the electronics and nuclear power fields, as well as in various structural components.

-

MESIC (highly slippery silicon carbide)

MESIC is a special type of SiC material that has sliding properties and high thermal conductivity, and is attracting attention for use in high sliding components and sintering setters.

Applications of Mino Ceramics

-

Electronic components, secondary batteries, fuel cells

-

Raw materials for various ceramics

-

Semiconductor manufacturing equipment

Types of Ceramics from Mino Ceramics

Firing Tools

Kiln Furniture

Kiln furniture (firing tools) with features such as ultra-rapid firing, reduced heat capacity, and uniform temperature distribution, are well received in heat treatment and firing processes for electronic components, advanced glass, parts for semiconductor manufacturing equipment, secondary batteries, fuel cells, and various ceramic materials.

Oxide and Non-oxide Ceramics

Fine Ceramics

We provide distinctive fine ceramics (oxide and non-oxide) to the electronics industry and various other advanced fields. In addition, by using a different manufacturing method, we are able to achieve not only cost reductions but also applications in fields that have never been seen before.

Ultra-high pressure and high temperature technology

Ceramics pressure medium

This technology is incorporated in high-temperature, high-pressure devices such as multi-anvils, and has contributed to research in geology, as well as to the production of synthetic diamonds in recent years.

Supporting Advanced

Fields with New Ceramics

Mino Ceramics is expanding into a variety of advanced fields, including the electronics industry, as well as structural components using oxide and non-oxide ceramics.

Mino Ceramics provides superior quality oxide ceramics (alumina, mullite, zirconia, cordierite, etc.) and non-oxide ceramics (SiC, B4C, etc.) to a variety of leading-edge fields using a unique manufacturing process that precisely controls raw materials and manufacturing processes.

Our motto is to provide products that meet detailed requirements and satisfy our customers. Oxide and non-oxide ceramics made with our original manufacturing technology are used in various advanced research fields as well as in consumer applications.